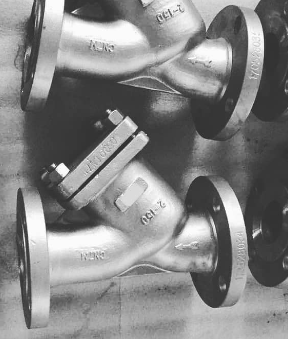

Y Strainer Manufacturer in Canada is to remove unwanted particles from steam, gasses, and liquids using a straining element, typically made of wire mesh. It is used in industrial pipelines to protect pumps and steam traps. Some Y-type strainers are constructed with blow-off valves to make cleaning simpler and more convenient.

Working:

Fluid enters the Y strainer through the inlet port and flows through the filter leg. The mesh screen traps particles, debris, and other foreign matter that’s larger than the screen openings. The debris-free liquid exits the filter basket and is discharged from the Y strainer through the filter outlet. Over time, debris accumulates in the filter basket, so it needs to be cleaned regularly.

Advantages:

Y Strainer Manufacturer in Canada can be installed vertically or horizontally, making them versatile and easy to install.

They are cost-effective options, and their size can be reduced to cut on initial costs.

They can be customized in a variety of ways, including the material they are made from.

They are ideal for pipeline applications because of their compact design

They have built-in blow-down ports that provide superior flushing capabilities

They allow for cleaning without the need for system shutdown.

Y Strainer Manufacturer in Canada below are the industries:

Chemical processing

Petroleum

Power generation

Water treatment

Marine

Natural gas

Pipelines

Components:

Filter element: This is the part that strains out particulates and can be made of mesh, perforated metal, or wedge wire straining element. Wire mesh is the most common type of straining element.

Housing: The body of a Y strainer is usually made of cast iron or cast steel.

Cover plate: A Y strainer also includes a cover plate.

Coupling: A Y strainer also includes a coupling.

High voltage nut bolts: A Y strainer also includes high voltage nut bolts.

Blow-off valves: Some Y strainers include blow-off valves to make cleaning easier.

Description:

Available materials: WCB, WC6, WCC, LCB, LCC, CF8, CF8M, cast iron, SS304, SS316, ductile iron, Carbon steel (ASTM A105, ASTM A516), Stainless Steel (ASTM A182 F304, ASTM A182 F316), Brass (ASTM B16, ASTM B124)

Class: 125 to 300

Nominal Pressure: PN6 to PN25

Size: ½” to 32”

Ends- Flanged, threaded, Buttweld, socket weld