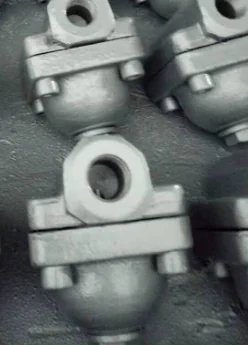

Thermodynamic Steam Trap Manufacturer in Canada have a unique operating principle which relies on the dynamics of water and flash steam. They are simple, robust and reliable and can operate up to very high temperatures and pressures

Working:

Thermodynamic Steam Trap Manufacturer in Canada work by using the difference in forces acting on the top and bottom sides of a valve disc to open and close the valve. The valve opens to discharge condensate for a few seconds and then closes for a longer period.

Advantage:

They are small and lightweight, but have a large capacity for condensate.

They can be used on high pressure and superheated steam.

Thermodynamic Steam Trap Manufacturer in Canada they are made of stainless steel, which makes them resistant to corrosive condensate

They have only one moving part, the disc, so they are easy to maintain and service without removing them from the line.

They make a clicking sound when they open and close, which makes them easy to test.

They are unlikely to freeze if they are installed with the disc in a vertical plane.

They are not affected by water hammer or vibration.

Industries:

Pulp and paper

Petrochemical and chemical

Textile

Components:

Piston: A hollow piston that works inside a tapered piston that acts as a guide

Piston disc: A disc that works with the piston

Main valve: A valve that rests on a seat when the trap starts up

Seat: The seat that the main valve rests on when the trap starts up

Clearance: A clearance between the piston and cylinder

Hole: A hole at the top of the piston

Description:

Material: Ductile iron, Cast Iron, Carbon Steel, cast steel (WCB, WCC, LCC, LCB, WC6, WC9), Stainless Steel (SS316, SS304, CF8).

Class: 150 – 1500, PN10 – PN250.

Size: ½” to 2”.

Ends: Socket weld, butt weld, flanged, threaded.