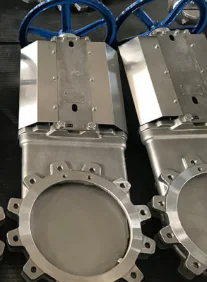

A leading Super Duplex Knife Gate Valve Supplier in Ohio is just one of the patterns of valves, which are especially intended to be used in managing fluid flow within pipelines, with particular environments that handle slurry, thick liquids, or any other challenging materials. It is fabricated from super duplex stainless steel, which provides durability and resistance to corrosion.

The valve works with a flat, sharp-edged gate-or a blade-that responds up and down inside the valve body to hold the flow. When fully opened, the valve lifts the gate out of the flow path, and fluids are allowed to pass through with little resistance. When closed, it allows the gate to descend into the seat, effectively cutting through the fluid, and creates a tight seal to ensure no leakage can occur.

Advantages of Super Duplex knife Gate Valve

High resistance to corrosion: since it constitutes super duplex stainless steel, it has excellent resistance against strong chemicals and corrosive atmospheres.

Strength-Durable Material: A leading Super Duplex Knife Gate Valve Supplier in Ohio resists high pressure and temperatures to ensure long-term reliability.

Smooth Operation: Sharp Edged entrance gate cuts through thick or abrasive material for positive shut-off and flow control.

Minimal Maintenance: The durability of the design contributes to minimal needs for maintenance and prolongs the service life.

Versatility: From slurries to particulate-laden fluids, all can be managed by this design.

Industries of Super Duplex knife Gate Valve:

Chemical Processing: Control of corrosive chemicals and abrasive slurries during production and handling.

Mining: Slurry flow control in mines and processing plants particularly those with thick, particulate-laden slurries.

Wastewater Treatment: Sludge and other wastewater materials are passed through the flow control in the plants.