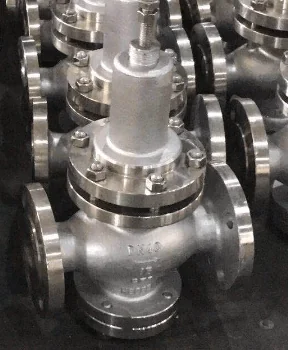

Steam Pressure Reducing Valve Manufacturer in Canada

A Steam Pressure Reducing Valve Manufacturer in Canada is a device that regulates steam pressure to a safe and constant level and is a critical component of steam systems. They are used in a variety of applications, such as oil lines, testing fixtures, autoclaves, steam tables/irons, single radiators, and vulcanizers. It works by constricting part of the flow path to reduce pressure. They automatically adjust to maintain the desired pressure level and compensate for fluctuations in steam flow.

Working:

When the outlet pressure drops below the set point, the spring pressure overcomes the outlet pressure and opens the valve. When the outlet pressure increases, the pressure under the diaphragm overcomes the spring pressure and closes the valve

Advantages:

1. Steam Pressure Reducing Valve Manufacturer in Canada have a long service life.

2. They help improve the quality of the material being heated.

3. They can quickly sense and adjust based on the downstream pressure.

4. They don’t need an external power source.

eliminate external leakage and high friction because they don’t have stem packing.

5. Protects equipment

6. Maintains optimal working conditions

7. Improves quality of heated material

Industries:

1. Textiles

2. Chemical processing

3. Pulp and paper

4. Paper mills

Components:

1. Valve body: Stabilizes the flow return and regulates pressure

2. Diaphragm: Controls the valve’s position against the spring pressure

3. Adjustment spring and screw: Work together with the diaphragm to control the valve position

4. Plug stem with plug and balancing bellows: A component of the valve body

5. Actuator with the operating diaphragm: A component of the valve body

6. Inlet port: A component of the valve

7. Outlet port: A component of the valve

8. Orifice: A component of the valve

Description:

1. Available materials: Ductile Iron, WCB, WCC, WC6, LCB, LCC, SS304, SS316, Cast iron

2. Size: 1/2″ to 24″

3. Nominal Pressure: PN10 to PN100

4. Class: 150 to 600

5. Ends: Threaded, Buttweld, Socket weld, Flanged