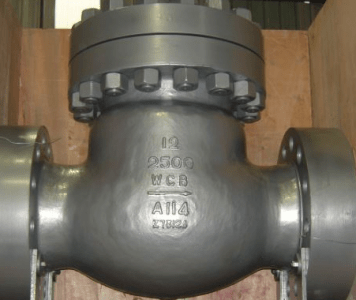

A Pressure Seal Check Valve Manufacturer in Canada is a type of check valve that allows flow in one direction and protects systems from reverse flow. They are used in a variety of applications, including power plants, boilers, and steam stations

Functions:

A pressure seal is a valve design concept that offers distinct advantages when compared to a conventional bolted body-to-bonnet sealing mechanism. It uses the valve system pressure to provide sufficient forces against the valve body’s internal diameter and the bonnet surfaces. As the system pressure increases, the force on the pressure seal gasket also increases. Although the only working part of the gasket is the apex or toe, the pressure seal conforms to the inside diameter of the valve.

Advantages:

Leak-free sealing: Pressure Seal Check Valve Manufacturer in Canada use the system’s pressure to create a seal, which minimizes the risk of leaks.

High-pressure performance: Pressure seal check valves are reliable and perform well at high pressures.

Reduced maintenance: Pressure seal check valves are durable and require less maintenance.

Versatile applications: Pressure seal check valves can be used in a variety of industries.

Compact cage unit: The moving parts of a pressure seal check valve are attached to a hanger block or ring, making them easy to remove for service.

No hinge pin penetration: The hinge pin of a pressure seal check valve doesn’t penetrate the outside, which eliminates pin seal leakage.

Pressure Seal Check Valve Manufacturer in Canada below are the industries:

Oil and gas

Oil and gas industry.

Power generation industry

Petrochemicals industry

Components:

Body: Centre of the internal valve parts and provides a passage for fluid flow

Disc: The disc is a key component of a check valve

Seat: A key component of a check valve

Cover: A key component of a check valve