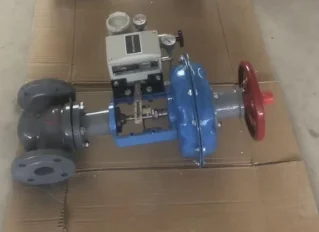

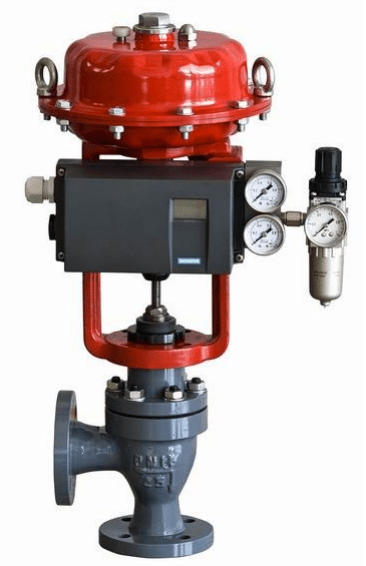

Pneumatic Control Valve Manufacturer in USA divert the flow of control air from one port to another, which feeds other pneumatic valves with signals, or opens and closes pneumatic actuators. This valve is an air close, spring open, globe valve.

Design:

Position Indicator:

Valves are often fitted with a position indicator. Green or yellow is used to symbolize open, whilst red symbolizes closed; the letters O and S are also used to indicate open and closed respectively.

Actuator:

An actuator is used to actuate change the position of a valve.

Body:

The body forms the main pressure boundary of all valves and must be constructed from suitable materials to withstand the service pressure to which it will be subjected.

Disc:

Valves are often named after the type of disc they employ e.g. ball valve, plug valve etc. Discs may be linearly actuated; this valve is a linearly actuated straight-body globe valve.

Seat:

The valve disc presses against the valve seat. It is imperative that the disc and seat surfaces remain clean. If the seat or disc surfaces are damaged, or not clean, it will not be possible to obtain a seal between the seat and disc; this will lead to the valve passing (leaking) when in the closed position.

Diaphragm:

A diaphragm separates the lower and upper parts of the diaphragm case.

Air Inlet:

Pneumatic air is supplied to the diaphragm casing through this connection. A solenoid bleed valve would be installed on the supply line to bleed the pressure from the diaphragm casing when desired.

Function:

Pneumatic Control Valve Manufacturer in USA divert the flow of control air from one port to another, which feeds other pneumatic valves with signals, or opens and closes pneumatic actuators.

Advantages:

1. Cost-efficiency,

2. Simplified installation,

3. Reduced space claim, and.

4. Increased safety.

5. Pneumatic Control Valve Manufacturer in USA below are the industries:

6. Oil and gas

7. Automation industry

8. Manufacturing industry

Description:

1. Material: Duplex Steel, Forged Steel, Ductile Iron, Cast Iron, F304, F304L, F316, F316L, 316L, F51, F53, 4A, 5A, WCB, SS316 and SS304.

2. Class: 150 to 2500

3. Ends: Flanged, Socket weld, Butt weld, Threaded.

4. Size: ½’’ to 24’’

5. Pressure: PN10 – PN450

6. Operation: pneumatic actuated.