Non Slam Swing Check Valve Manufacturer in USA

Non Slam Swing Check Valve Manufacturer in USA used to prevent reverse fluid flow. Also, these valves are meant to eliminate or reduce water hammer and their associated effects. A water hammer is a high-pressure shock wave that happens when the fluid flow stops abruptly because of a pump or valve closing quickly in a piping system. When a water hammer happens, the fluid flow reversal causes high stress on the piping system which endangers its structural integrity and may cause damage or rupture. Non-slam check valves are used to prevent water hammers and ensure fluid flows in one direction only.

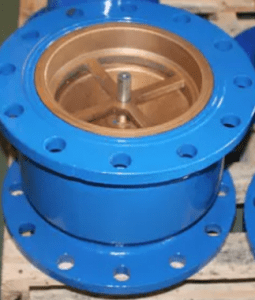

Design:

Lifting non-slam check valve are divided into vertical and horizontal.

Rotary non-slam check valve can be divided into three types: single-lobe, double-lobe, and multi-lobe.

Butterfly non-slam check valve is straight-through.

Function:

A non-slam check valve works based on differential pressure. When the upstream pressure is high, it provides enough pressure energy that is used to open the valve disc. The disc is supported by the use of a spring. As such, the pressure energy compresses the disc to open. When the disc opens, fluid flows through the valve from the inlet to the outlet port and finally to the piping system. The valve closes when fluid pressure reduces.

Advantages:

Non Slam Swing Check Valve Manufacturer in USA prevent water hammers from occurring.

These valves have a low-pressure drop.

These valves can maintain the required fluid pressure.

They do not allow reverse fluid flow.

These valves can be installed in vertical or horizontal orientation.

They are automatic valves.

These valves are cheaper relative to other valves.

They are versatile and durable

Non Slam Swing Check Valve Manufacturer in USA below are the industries:

Oil and gas

Water and wastewater treatment

Power generation

HVAC