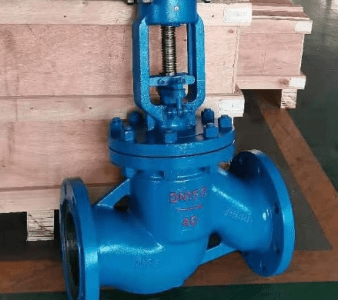

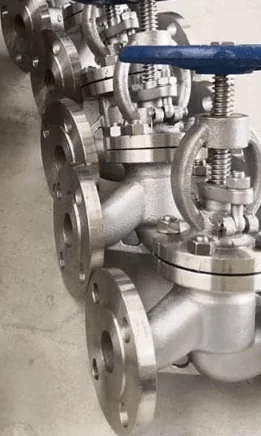

Bellow Seal Globe Valve Manufacturer in USA

SVR Global is the best Bellow seal globe valve manufacturer in USA supplying good quality valves to oil and gas industries, power generation industries and chemical industries in Los Angeles, Houston and Dallas. A below-seal globe valve is a type of globe valve where the valve seat is positioned below the valve disk. The valve disk is moved up and down by the valve stem to control the flow of fluid through the valve.

The valve is specifically designed to balance and regulate pressure according to its desired value. Unlike other valves, this valve is equipped with a bellow, ensuring a fully closed valve and no leakage. It does not require a flow rate and effectively prevents fluid loss while maintaining a tight seal. The bellow is strategically positioned to protect the stem from fluid flow damage, with the other end placed between the body and the cover to create a double seal, ensuring safety and a tight seal. This valve’s compact structure and design provide efficient pressure control, making it easy to use and reliable throughout its lifespan.

Parts:

Body: The main housing of the valve that contains the internal components.

Bonnet: The top cover of the valve body that provides access to the internal components.

Disc: The valve element that controls the flow of fluid through the valve by moving up and down to open and close the valve.

Stem: The component that connects the disc to the actuator and controls its movement.

Seat: The sealing surface against which the disc closes to prevent leakage when the valve is closed.

Bellow: The flexible component that provides a seal between the valve stem and bonnet to prevent leakage.

Gland: The component that compresses the bellow and ensures a tight seal.

Packing: The material used to seal the stem and prevent leakage around the gland.

Handwheel or actuator: The component used to operate the valve, either manually or through an automated system.

Flanges: The components used to connect the valve to the pipeline

Industries:

Electric power industry.

Textile industry.

Petroleum industry

Oil & Gas Industry

Mining Industry

Natural Gas

LPG & LNG.

Paper & Pulp.

Chemical Industry.

Petrochemical Industry.

Applications:

Chemical industry: Bellow seal globe valves are widely used in the chemical industry due to their excellent resistance to corrosive chemicals, high-pressure and temperature resistance, and tight shut-off.

Oil and gas industry: Bellow seal globe valves are commonly used in the oil and gas industry for controlling the flow of fluids, gases, and steam. They are suitable for high-pressure applications and can withstand extreme temperatures.

Power plants: Bellow seal globe valves are used in power plants for controlling the flow of steam and water in high-pressure and high-temperatures.

Advantages:

Prevents leakage: The bellow seal design ensures a tight seal between the stem and bonnet, preventing fluid leakage.

Low maintenance: Bellow seal globe valves require less maintenance than other types of valves because the bellow act as a barrier between the process fluid and the valve stem, preventing the buildup of debris.

Extended lifespan: they generally have a longer lifespan than other types of valves.

Easy installation: Bellow seal globe valves are easy to install, requiring only a few simple steps to connect the valve to the pipeline.

Chemical processing: Bellow seal globe valves are commonly used in the chemical processing industry to control the flow of corrosive or toxic fluids.

Oil and gas industry: Bellow seal globe valves are used in the oil and gas industry to control the flow of natural gas, crude oil, and other fluids.

Power generation: Bellow seal globe valves are used in power plants to control the flow of steam and other fluids.

Water treatment: Bellow seal globe valves are used in water treatment plants to control the flow of water and other fluids.

SVR Global, the Bellow seal globe valve manufacturer in USA provides valves with the following description:

Available materials: WCB, WC6, SS304, SS316, F11, F51, F91, LCC, LCB, WC

Ends: Flanged, Buttweld, Socketweld, Threaded

Class: 150 to 2500

Nominal Pressure: PN25 to PN450

Size: ½” to 24”

Operations: Hand-wheel operated, Pneumatic actuated, Electric actuated, Gear operated