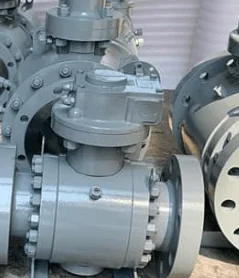

Trunnion Ball Valve Manufacturer in USA

SVR Global is the best Trunnion ball valve manufacturer in USA. We provide high-quality valves to the oil & gas, mining, and maritime sectors in Phoenix, Dallas, and Oregon. A specific kind of ball valve used in industrial settings to control fluid or gas flow is the trunnion ball valve. Its name comes from the trunnion, a permanent support that holds the ball firmly in place and permits rotation. A hollow ball with a hole in the middle serves as the valve’s passageway for liquid or gas. When the valve is open, the actuator or handle of the valve is turned, causing the ball to rotate and allowing fluid or gas to pass through the hole. Once the valve is shut, the ball rotates once more to stop the flow.

Parts:

Body

Ball

Trunnion

Seats

Stem

Actuator

Gaskets

Bolts

End connections

Types:

Casting trunnion ball valve: A casting trunnion ball valve is made by pouring molten metal into a mold to form the valve body and other components. The metal solidifies and cools in the mold to create a finished valve. This process is commonly used for large size valves where the cost of forging would be prohibitive.

Forged Trunnion Ball Valve: A forged trunnion ball valve, on the other hand, is made by heating a metal bar or billet and shaping it using mechanical force and pressure. The result is a finished valve with greater strength and structural integrity compared to a casting valve. Forged trunnion ball valves are usually smaller in size and are used in applications where high-pressure, high-temperature, or corrosive conditions exist.

Industries:

Chemical Processing industry

Power Generation industry

Petrochemical industry

Oil and Gas industry

Water and Waste treatment industry

Marine industry

Mining industry

Applications:

Oil and gas pipelines for transportation and distribution.

Petrochemical and chemical processing plants for fluid handling and control.

Power plants for steam and water control.

Water treatment facilities for flow control.

Mining operations for slurry control.

Fire protection systems for water flow control.

Fuel storage and distribution systems for petroleum products and chemicals.

Transportation of slurries and other viscous materials in the mining industry.

Cryogenic applications for handling liquefied gases, such as nitrogen and oxygen.

Advantages:

Stronger in structure

Lower running costs.

Offers reliable sealing with minimal leakage.

Resistant to corrosion and erosion.

Easy to operate and maintain.

Can be used in a wide range of applications and industries.

Low operating torque, making them easy to operate and reducing wear on valve components.

Can handle abrasive materials without significant wear or damage to the valve.

Have a longer service life compared to other types of valves.

Can be designed and manufactured to meet specific application requirements.

Can be used in a wide range of temperatures, from cryogenic to high-temperature applications.

SVR Global, the Trunnion ball valve manufacturer in USA provide valves known for their durability, reliability, and ease of maintenance. These valved are available in various sizes and for different pressure classes.

Description:

Body Material: Cast steel (WCB, WCC, WC6, LCC, LCB), Titanium, Stainless steel (SS316, SS304, F51, F55, CF8, CF8M).

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld, Socket weld, Flanged

Operations: lever and Gear Operated, Electric and pneumatic operated.