A Titanium Butterfly Valve Supplier in Minnesota is a fluid control device that’s made of titanium, a non-ferrous metal, and is used to change the flow direction and passage section of a medium. Titanium butterfly valves are known for their corrosion resistance, tensile strength, and lightweight nature.

Working:

A Titanium Butterfly Valve Supplier in Minnesota works like a standard butterfly valve, which uses a rotating disc to control the flow of a fluid. The valve is opened or closed by rotating the disc 90 degrees. When the disc is parallel to the flow, the valve is open, and fluid can pass through. When the disc is perpendicular to the flow, the valve is closed and blocks the flow.

Advantages:

Its strength and resistance to corrosion, even in harsh environments. Titanium alloys have a high strength-to-weight ratio compared to other metals.

Maintain their integrity in systems that generate extreme heat, preventing warping or failure.

Titanium Butterfly Valve Supplier in Minnesota are easy to maintain because they have a simple design with fewer parts.

Industries:

Chemical industry

Oil and gas industry

Power generation

HVAC

Water and wastewater treatment

Metal-mineral processing

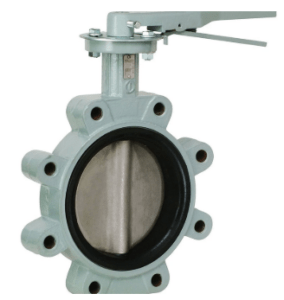

Components:

Valve body: Located between the pipe flanges, the valve body holds the valve components in place. It can be made from titanium alloy, which is lightweight, corrosion-resistant, and has a high strength-to-weight ratio.

Disc: The disc is usually made from stainless steel or aluminum bronze. Stainless steel is resistant to corrosion and oxidation, and aluminum bronze is heat treatable and has the strength of steel.

Seat: A component of the butterfly valve.

Operator or valve handle: A component of the butterfly valve.