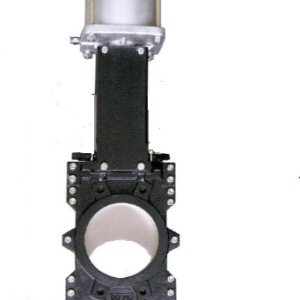

As a leading Through Conduit Knife Gate Valve Manufacturer in USA it is designed to lower down pressure drop and maximize flow potential. A through conduit knife gate valve is a type of valve that has an even flow path and is utilized to handle liquid and slurries with giant rigid content. The valves are being utilized in extensive range of commercial industries

Functions

Installation: The valve is being install in between pipeline flange

Rapid Flow Rate: The valve have rapid flow degree value offers high flow rate with lower pressure drop

Advantages

Unclosed Shut Off: As a leading Through Conduit Knife Gate Valve Manufacturer in USA, valve’s double seat design makes that there is non-clogging shut off

Multi Purpose Use in Variety Of Application: The Through Conduit Knife Gate Valve is being utilized in variety of application such as wastewater treatment, mining operations, power generation and steel manufacturing

Industries Using

Wastewater Treatment Plant: The through conduit knife gate valve manage sewage sludge and other rigid waste

Mining Operations: The valves helps to support transferring ore slurries and mining byproducts

Pulp and Paper Production: The valve are being utilized for handling paper pulp with high thread content

Power Generation: The valve are also being for power generation

Cement Plants: They are also used in cement plants industry

Steel Manufacturing: In Steel Manufacturing Industry Also the valve is being used

Chemical Processing: The valve are utilized to move thick chemicals and slurries

Power Plant: The valve are being utilized in ash handling system

Components

Body: The body of a valve is a major component as it is full port design low down and maximizes flow potential

Gate: Gate is a rigid chrome coated for more good corrosion resistance. The gate stops media clogging in the valve body cavity. The Gate surface is very well polished on both sides less jamming and tight seal