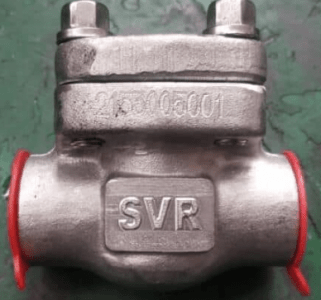

Swing Check Valve Manufacturer in USA

SVR Global is the leading Swing check valve manufacturer in USA . In Texas, Vermont, and Utah, we provide premium valves to the pipeline, water, wastewater, and marine industries. An example of a valve used to regulate fluid flow in a pipeline is a swing check valve. It works by employing a swinging disc or flap that only permits fluid passage in one direction while impeding fluid flow in the other. A swinging disc or flap that is hinged inside the valve body and has two openings an inlet and an outlet make up the valve. The disc is pushed open and the valve is opened when the fluid is flowing in the right direction. The disc swings shut to stop the fluid from flowing backward when the flow reverses. In water supply systems, wastewater treatment facilities, and other industrial applications where backflow prevention is necessary, these valves are frequently utilized. They are well suited for situations where energy efficiency is a priority because of their low pressure drop and minimal head loss characteristics. They are a popular option for many applications because they are also simple to deploy and maintain.

Parts:

A swing check valve typically consists of the following parts:

Body: The main housing of the valve that contains the other components and connects to the pipeline.

Disc or flap: The movable component that swings on a hinge to allow or block the flow of fluid through the valve.

Hinge pin: A rod or pin that connects the disc to the valve body and allows it to swing open and closed.

Spring: A component that is sometimes used to help close the disc and prevent fluid from leaking through the valve.

Seat: The surface against which the disc or flap closes to create a seal and prevent backflow.

Retainer: A component that helps hold the disc or flap in place and prevent it from swinging too far open or closed.

O-rings or gaskets: Sealing components that help prevent leaks around the valve body and between the body and the disc or flap.

Industries:

Chemical Industry

Pulp and paper Industry

Marine Industry

Mining Industry

Power Generation Industry

Oil and Gas Industry

Nuclear Industry

Petrochemical Industry

Applications:

Water supply and distribution: Swing check valves are commonly used in water supply and distribution systems to prevent backflow and protect against contamination.

Wastewater treatment: Swing check valves are used in wastewater treatment plants to prevent backflow and protect against contamination, as well as to regulate flow and pressure.

Oil and gas industry: Swing check valves are used in the oil and gas industry to prevent backflow and protect against contamination, as well as to regulate flow and pressure in pipelines and other equipment.

Chemical industry: Swing check valves are used in the chemical industry to prevent backflow and protect against contamination, as well as to regulate flow and pressure in pipelines and other equipment.

Mining industry: Swing check valves are used in the mining industry to prevent backflow and protect against contamination, as well as to regulate flow and pressure in pipelines and other equipment.

Advantages:

Low resistance to flow: Swing check valves have a streamlined design that creates minimal resistance to fluid flow, which reduces pressure drop and energy consumption.

Simple design: Swing check valves have a simple design that makes them easy to install, operate, and maintain, with few moving parts that can wear out or break.

Prevent backflow: Swing check valves are designed to prevent backflow, which can damage pumps, compressors, and other equipment, and cause contamination or other hazards.

Low cost: Swing check valves are relatively inexpensive compared to other types of valves, making them a cost-effective option for many applications.

Low maintenance: With few moving parts and a simple design, swing check valves require minimal maintenance and can provide reliable performance for long periods of time.

Wide range of materials: Swing check valves can be made from a wide range of materials, including metals, and elastomers, to suit various applications.

Fast-acting: Swing check valves respond quickly to changes in flow direction, allowing them to prevent backflow and minimize the risk of damage to equipment or processes.

High flow capacity: Swing check valves have a high flow capacity, allowing them to handle large volumes of fluid with minimal pressure drop.

Wide range of sizes: Swing check valves are available in a wide range of sizes, from small valves used in plumbing systems to large valves used in industrial applications.

Corrosion resistance: Swing check valves can be made from corrosion-resistant materials, such as stainless steel , to protect against the effects of corrosion.

SVR Global, the Swing Check Valve Manufacturer in USA manufactures leak-proof and durable valves at cost-effective prices.

Body Material: Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), WCB, SS304, 316L, Duplex Steel, 904L, Aluminum bronze, Stainless Steel [ SS316 , SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3,F55, F91 ]

Class: 150LB – 2500LB

Size: ½” – 40”

Ends: butt weld, socket weld, threaded, flanged