Strainer Manufacturer in USA

SVR Global is the top Strainer manufacturer in USA delivering strainers to water, chemical and oil & gas sectors. In order to prevent damage to downstream equipment and save maintenance costs, solid particles and trash from a fluid stream are filtered out by a strainer. A perforated or mesh screen, referred to as the strainer element, is fitted inside a housing to make up the strainer.

While still allowing fluid to pass through, the strainer element catches solid particles and trash as it passes through the fluid. In many different sectors, including chemical processing, oil and gas extraction, and water treatment, strainers are often utilized.

Types:

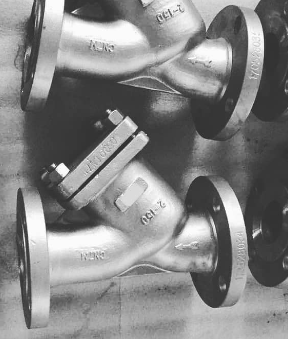

Y-Type Strainers

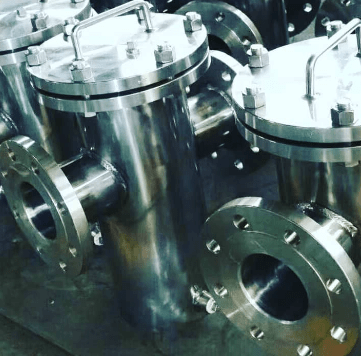

Basket Strainers

Duplex Strainers

Industries:

Oil and Gas Industry

Mining Industry

Water Treatment Industry

Chemical Industry

Paper and Pulp Industry

Manufacturing Industry

Automobile Industry

Applications:

Damage prevention for equipment farther down the line.

Pre-filtration for further filtering techniques.

The elimination of sand and debris from water sources.

Preventing clogging of valves and pumps.

Elimination of foreign material from heat exchanger cooling water.

Process water filtration in industrial production.

Hydraulic fluid filtration in large machines.

Cleaning up debris from gas pipes.

Seawater filtration in maritime industry.

Advantages:

Better product quality: Strainers may aid in ensuring that only pure and clean fluids are utilised in manufacturing operations, improving the quality of the final product.

Economical: Compared to other filtering systems, strainers are generally affordable to install and maintain, making them an economical choice for eliminating solid particles from fluid streams.

Versatile: Strainers are a flexible option for filtering fluids since they may be utilised in a variety of applications and industries.

Simple installation: Strainers may be adapted to existing pipe systems without requiring major adjustments.

Low pressure drop: Because strainers have a low pressure drop across the strainer element, the flow velocity of the fluid stream is not greatly affected by them.

Simple to clean: Strainers are simple to clean, and some varieties have detachable strainer parts that may be cleaned or changed as necessary.

Prevents clogging: Strainers can aid in preventing clogging and blockages in the fluid stream by eliminating solid particles and debris.

Minimizes downtime: Maintaining strainers regularly can assist to avoid equipment downtime due to blockage or damage brought on by solid particles in the fluid stream.

Environmentally friendly: By restricting the flow of polluted fluid into streams or sewage systems, strainers can contribute to environmental protection.

Lowers maintenance expenses: Strainers can assist lower maintenance costs related to equipment repairs and replacements by avoiding blockage and safeguarding downstream equipment from harm.

Description:

Available materials: Carbon Steel, CF8, CF8M, CF3M, Cast Iron, SS304, SS316

Class: 125 to 300

Nominal Pressure: PN6 to PN25

Size: ½” to 32”.

Ends: Buttweld, Flanged, Socket weld, Threaded