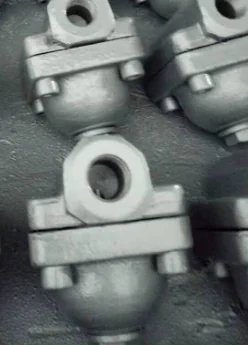

As a topmost Steam Trap Manufacturer in Canada this valve removes condensate and incondensable gas from a facility’s steam system, without leaking steam. It’s an automatic valve that opens, closes, and regulates autonomously.

Steam traps are just one component of a facility’s larger steam system. A full steam system will have many steam traps. They are usually placed at these locations

A Steam trap is an automatic drain valve which distinguishes between steam and condensate. A steam trap holds back steam & discharges condensate under varying pressures or loads. The steam traps should have good capacity to vent out air and other non-condensable gases quickly while holding back the live steam

Design:

Water Hammer: Highly resistant against corrosive condensate and water hammer.

Body: main component to preventing

Temperature indicator: Condate is discharged below the steam temperature

Function:

On start-up, steam enters the system only as fast as the air is vented.

An air steam mixture has a temperature well below steam temperature lowering the heat transferred.

Air is an insulator and clings to the surface of the pipe or vessel causing slow and uneven heat transfer.

Dissolved in condensate, the non-condensable gases from acid which corrode the system.

Advantages:

Discharge condensate as soon as it is formed

Have a negligible steam consumption (i.e. be energy efficient)

As a topmost Steam Trap Manufacturer in Canada the valves have the capability of discharging air and other non-condensable gases

Industries:

Chemical and petrochemical

Oil and gas

Description:

Available materials: Cast Iron, Ductile Iron, Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Stainless Steel (SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316), A105.

Size: 1/2″ to 4″

Nominal Pressure: PN10 to PN250

Class: 150 to 1500

Ends: Flanged, Buttweld, Socketweld, Threaded