Pneumatic Actuated Valve Manufacturer in USA

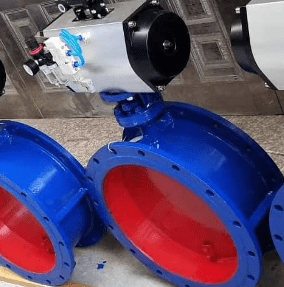

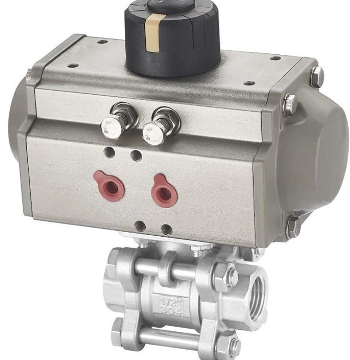

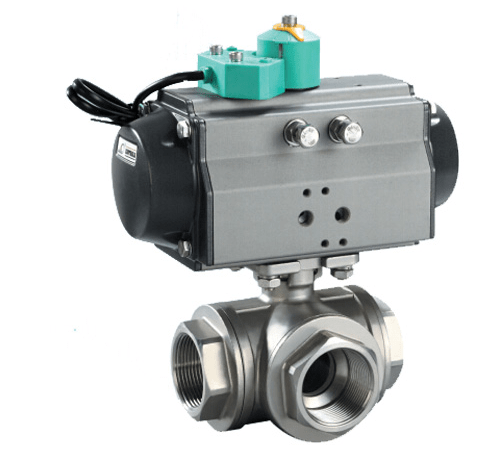

A Pneumatic Actuated Valve Manufacturer in USA transforms energy into mechanical motion. They are also known as air cylinders, air actuators, and pneumatic cylinders within the industry, yet they are all the same thing. The pneumatic actuator valve can move linearly up and down or 90 degrees horizontally, depending on the type of valve. The existence of some type of pressurized gas or compressed air entering a chamber where pressure is built up is necessary for pneumatic actuators. In contrast to the air pressure outside the chamber, once this rises above the necessary pressure levels, it causes a controlled kinetic movement of a piston or gear that can be directed in either a straight or circular mechanical motion. Depending on the requirements of the application, pneumatic rotary actuators are better suitable for fitting to quarter-turn valves than linear actuators for angle seat control valves made for high temperature and steam applications. A piston inside a closed cylinder is operated by pneumatically activated valves. The actuator is propelled by pressure from an external air or gas source, which moves the cylinder to completely open or close the valve or to vary its open/close movement.

Types:

Below are the types of Pneumatic Actuated Valve Manufacturer in USA:

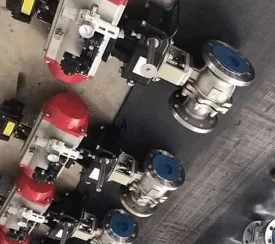

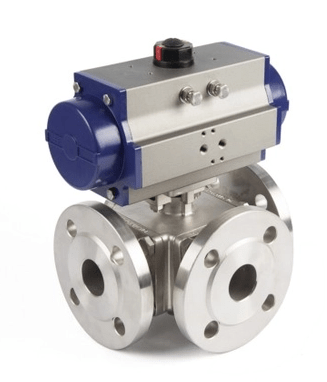

Pneumatic Actuated Ball valve

Pneumatic Actuated Gate valve

Pneumatic Actuated Butterfly valve

Pneumatic Actuated Knife Gate valve

Pneumatic actuated globe valve

Industries where Pneumatic Actuated Valve Manufacturer in USA, are used:

Water industry

Sewage industry

Power production industry

Oil and Gas Industry

Chemical Industry

Petrochemical Industry

Mining Industry

Marine Industry

Applications:

Controlling the flow of chemicals and other hazardous materials.

Used in the oil and gas industry to control the flow of oil, gas, and other fluids.

Used in the mining and minerals processing industry to control the flow of minerals, ores, and other materials in pipelines.

Used in power plants to control the flow of fluids.

Used in water and wastewater treatment plants.

Advantages:

They are very fast in operation

Helps in reducing labor cost

High performance and perform efficiently

Long life span of the product

Provide a reliable and a safe service throughout

Quick response time: Pneumatic actuators respond quickly to changes in control signals, allowing for fast and precise control of fluid flow.

Remote control

High reliability

Description:

Material: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150-2500, PN6-PN450

Size- ½’’-50’’

Ends: Flanged, Socket weld, Butt weld, Lug, Wafer, Threaded.

Operations: Pneumatic Actuated

Configuration of a Pneumatic Actuator:

Torque 3- 9000 nm

Operating pressure – 8 Bar

Port Connection – NPT1.4”

Mounting Base – ISO5211

Temperature – 20°C – +80°C