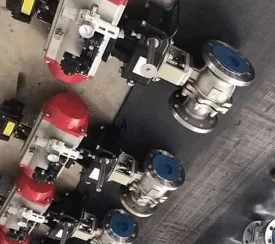

Pneumatic Actuated Ball Valve manufacturer in USA

A Pneumatic Actuated Ball Valve manufacturer in USA is a valve that uses compressed air to control the flow of a liquid or gas. The valve has a rotating ball with a bore that is controlled by a pneumatic actuator. The actuator converts compressed air energy into mechanical motion to turn the ball

Working

The actuator converts compressed air energy into mechanical motion that turns the valve. The air pressure is applied to a piston or bellows diaphragm, which creates a linear force on the valve stem. A single-acting actuator uses one compressed air input to turn the valve, while a double-acting actuator uses two compressed air inputs. A spring-return actuator uses springs to push the piston back and operate the other movement. This system provides a safety position in case of a power cut. A normally closed valve is held closed by a spring, while a normally open valve is open when the system is normal. The actuator can be operated remotely.

Pneumatic Actuated Ball Valve manufacturer in USA below are the advantages

Pneumatic actuated ball valves have a small fluid resistance.

Small, lightweight, and have a simple structure.

Valves are tight and reliable

Easy to operate and repair.

Durable and have a long operational life

Valves have low maintenance requirements.

Safe because they don’t require ignition or electricity, so they don’t pose a fire risk

Industries of Pneumatic Actuated Ball Valve manufacturer in USA

Power plants

Mining

Chemical handling

Water treatment

Wastewater handling

Automotive

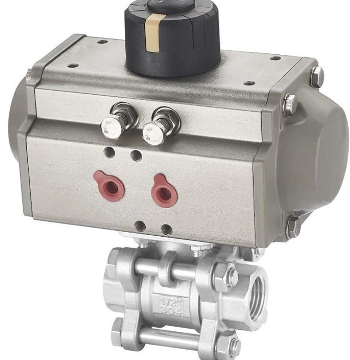

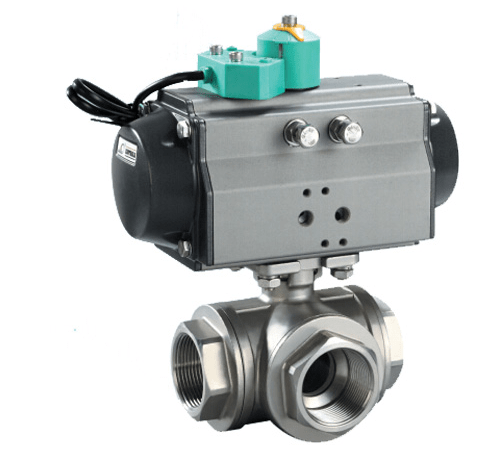

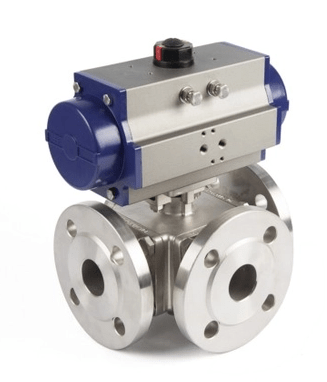

Components

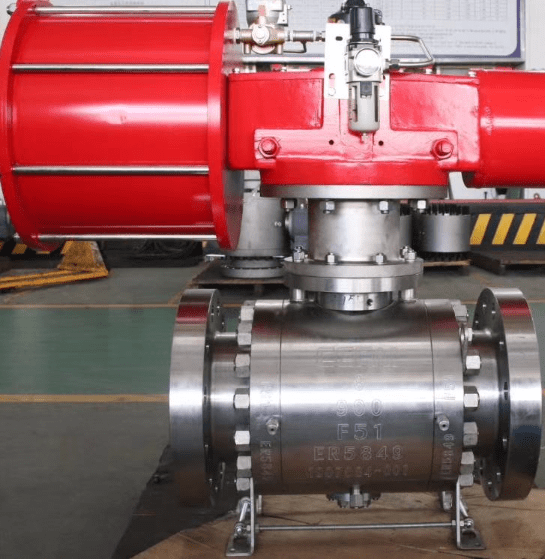

Pneumatic: Refers to the use of pressurized air or gas to create energy.

Actuator: The component that is used to automate control of the ball valve.

Ball Valve: A quarter-turn on/off valve that controls flow of media via a pivoting ball

Description

Body Material: Cast steel (WCB, WCC, WC6, LCC, LCB), Stainless steel (SS304, SS316), Carbon steel (CF8, CF8M),

Class: 150 to 2500; PN10 to PN450

Size: ½” to 4”

End: Buttweld, Flanged, Socketweld, Threaded

Operation: Pneumatic actuated ball valve