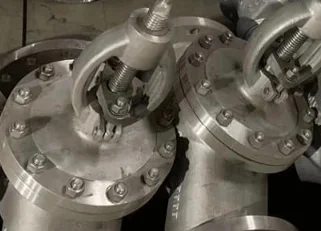

Leading Alloy 20 Globe Valve Manufacturer in Canada are made from chromium-nickel-molybdenum stainless steel alloy and are being utilized to control the flow of liquid in pipelines. The valve are being utilized in a variety of commercial industries such as chemical Industry, Power Plant and Plastics. Alloy 20 globe valve are proof-against to pitting and chloride ion corrosion and its copper content supports to protect it from sulfuric acid. As they are designed to standby in high temperature and pressure in dangerous surroundings

Functions

Easy Maintenance: The valve are easy to maintain and sanitize as the alloy 20 globe valve are made from non-magnetic, non-toxic substance

Balance of Fluid Flow: As the Alloy 20 Globe Valve are being used to control fluid flow in dangerous surroundings like as chemical industry and power plants

Ability to Handle Erosive Fluids: The Alloy 20 Globe Valve has the ability to handle a extensive range of chemicals, as nitric acid, chlorides, phosphoric acid , alkaline solutions and sulfuric acid

Anti Corrosion: The Alloy 20 Globe Valve are resistant to chloride ion corrosion, pitting and common corrosion. Their copper content protects them from Sulfuric Acid

Advantages

Lasting for Longer Period: The Alloy 20 Globe Valve are durable as they have tight sealing properties

High Pressure Resistance: Leading Alloy 20 Globe Valve Manufacturer in Canada can standby within high temperature and pressure

Industries Using

Cooling Water Systems

Wastewater Applications

Cleaning and Picking Lines

Condensate Systems

Chemical

Plastics

Gas Desulfurization Systems

Nitric Acid, Hydrochloric Acid and Sulfuric Pumps and Valves

Condensate Systems

Components

Valve Body: The body of the valve is main components as that connects all the internal parts

Stem: A stem connects the disc to an outer actuator or handwheel